Crafting Excellence in Titanium

At ARS, we take pride in crafting excellence in every piece of titanium we produce. With years of expertise in the industry, we’ve honed our skills to deliver top-notch quality and reliability in every product we offer. From aerospace to medical devices, our titanium solutions are trusted by industries worldwide for their durability, strength, and versatility.

Our dedication to innovation and customer satisfaction drives us to continually push the boundaries of titanium manufacturing. Whether you’re looking for titanium bars, sheets, or custom components, we have the expertise and resources to meet your needs. Explore our offerings and discover why ARS is the preferred choice for businesses seeking high-quality titanium solutions that stand the test of time.

Request a Free Quote

Explore Our Titanium Products

Diverse Titanium Offerings: Explore an Array of Titanium Products

At ARS, we offer a comprehensive range of titanium products to cater to various industry needs. From foil to powder, our inventory includes titanium sheet, plate, mesh, wire, rod, bar, tube, and more. Whatever your project demands, we have the titanium solution to match.

Customized Services: Tailored Titanium Solutions Just for You

In addition to our extensive product range, we also provide customized services to meet specific requirements. Whether you need a unique size, or shape, our team of experts is dedicated to delivering tailored titanium solutions that perfectly fit your project needs.

-

Titanium Plate

Titanium Plate -

Spherical Titanium Powder

Spherical Titanium Powder -

Nitinol Alloys

Nitinol Alloys -

Titanium Sponge

Titanium Sponge -

Custom Titanium Parts

Custom Titanium Parts -

Titanium Carbide Powder

Titanium Carbide Powder -

Titanium Carbonitride Powder

Titanium Carbonitride Powder -

Titanium Fasteners

Titanium Fasteners -

Titanium Fittings

Titanium Fittings -

Titanium Flange

Titanium Flange -

Titanium Sputtering Target

Titanium Sputtering Target -

Titanium Tube

Titanium Tube -

Titanium Bar

Titanium Bar -

Titanium Rod

Titanium Rod -

Titanium Sheet

Titanium Sheet -

Titanium Strip

Titanium Strip -

Titanium Wire

Titanium Wire -

Titanium Powder

Titanium Powder -

Titanium Mesh

Titanium Mesh -

Titanium Foil

Titanium Foil

Why Choose ARS-Our Advantages

Exceptional Quality

Our titanium products undergo rigorous quality control measures to ensure consistency and reliability, meeting the highest industry standards.

Wide Range of Options

From foil to powder and everything in between, we offer a diverse selection of titanium products to suit various applications and industries.

Customization Abilities

With our expertise and advanced manufacturing capabilities, we can tailor titanium products to your exact specifications, providing bespoke solutions for your projects.

Proven Durability

Renowned for its strength and corrosion resistance, titanium is a durable material that ensures longevity and performance in demanding environments.

Expertise and Experience

With years of experience in the titanium industry, our team possesses the knowledge and skills needed to deliver top-notch products and exceptional service.

Commitment to Customer Satisfaction

At ARS, we prioritize customer satisfaction above all else, striving to exceed expectations with prompt delivery, reliable support, and responsive communication.

Physical Properties of Titanium

| Phase | Std Atomic Weight | Melting Temperature | Boiling Point | Crystal Structure | Electrical Resistivity | Thermal Conductivity | Thermal Expansion |

|---|---|---|---|---|---|---|---|

| Solid | 47.867(1) g·mol−1 | 1941 K, 1668 °C, 3034 °F | 3560 K, 3287 °C, 5949 °F | Hexagonal | (20 °C) 0.420 µΩ·m | (300 K) 21.9 W·m−1·K−1 | (25 °C) 8.6 µm·m−1·K−1 |

Titanium Applications Across Industries

Aerospace

Titanium is a great choice for the manufacture of aerospace parts. It is often used to manufacture critical parts such as landing gear, firewalls, and hydraulic systems. Titanium is valued in the aerospace industry because of its low density, high strength-to-weight ratio, corrosion resistance, and fatigue resistance.

Automobile

Titanium is often used in the automotive industry to make engine parts, crankshafts, valve seats, connecting rods, exhaust systems, suspension systems, and automotive frames. Titanium is highly coveted in the automotive industry due to its low density, high strength-to-weight ratio, corrosion resistance, and heat resistance. Not only do these characteristics of titanium enable improved aerodynamics and performance, but its low density and high strength also lead to a more cost-effective manufacturing process.

Medical

Due to its inertness and non-toxicity, titanium is used in a wide array of medical applications including surgical implants, dental implants, surgical tools, and accessibility equipment.

Chemical

Titanium has excellent corrosion resistance and is widely used in chemical production. This material is beneficial for increasing production, improving product quality, extending equipment life, reducing consumption, reducing energy consumption, reducing costs, preventing pollution, improving labor conditions, and increasing labor productivity.

Marine

Titanium has a high level of corrosion resistance against seawater, making it a suitable component for ship rigs, propeller blades and shafts, and other parts submerged in water.

Sports

The high strength-to-weight ratio of titanium lends itself to a range of applications in the sports industry. The material is used as components of sporting goods such as tennis rackets, baseball bats, golf clubs, bike frames, and ski equipment.

Jewelry

Titanium is commonly used in jewelry to make piercings, wrist watches, necklaces, rings, and other items due to its durability, light weight, and corrosion resistance. Because of its biocompatibility, Titanium is popular among people who have allergies to other metals often found in jewelry.

Features of Titanium

Corrosion Resistant

Titanium is highly resistant to corrosion from seawater, chlorine, and many other corrosive agents, making it useful in marine, and chemical processing applications.

Lightweight

Titanium has a low density compared to many other metals. It is ideal for use in lightweight structures and components in the aerospace and automotive industries.

High Strength

Titanium’s strength rivals that of steel. A titanium structure of equivalent strength, however, weighs approximately 45% less than the corresponding steel structure because of titanium’s lower density.

Biocompatible

Titanium is considered the most biocompatible metal due to its inertness, its resistance to corrosion by bodily fluids, its capability to integrate into bone (osseointegration), and its high cyclic fatigue limit.

Heat Resistant

Titanium has low thermal conductivity. This makes titanium ideal for high-heat applications in machining, spacecraft, jet engines, missiles, and automobiles.

Ductile

Titanium is a ductile metal whose ductility improves with increased temperatures. Additionally, alloying titanium with other ductile metals like aluminum significantly improves its ductility.

Low Thermal Expansion

Titanium has a low coefficient of thermal expansion. At extreme temperatures, titanium will not expand or contract as much as other materials such as steel.

Excellent Fatigue Resistance

Titanium has excellent fatigue resistance. This makes titanium ideal for aerospace applications where structural parts of aircraft such as landing gear, hydraulic systems, and exhaust ducts are subjected to cyclic loading.

Quality Control of Titanium

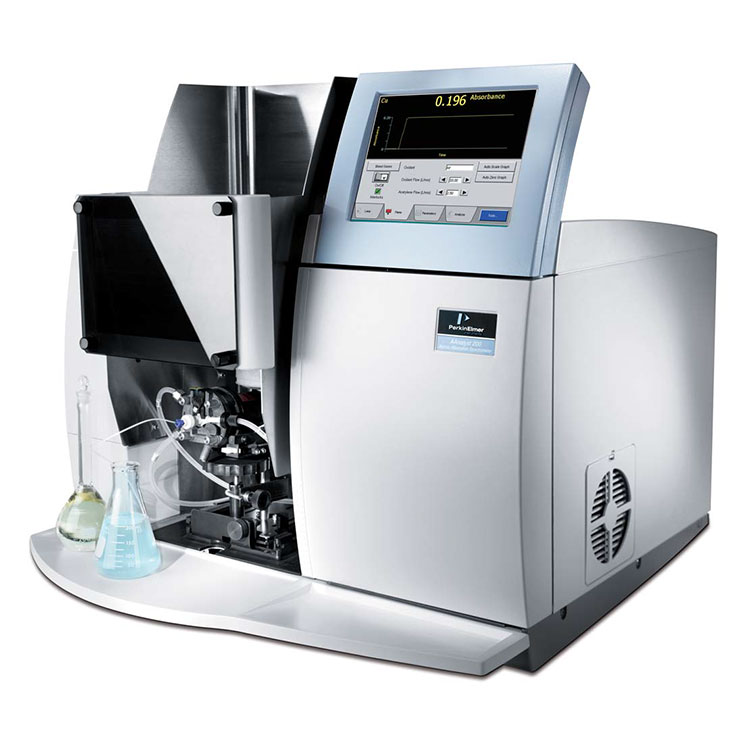

Atomic absorption spectrometry (AAS)

AAS is a commonly used quantitative analysis method, suitable for determining the titanium content in solution. The method is based on the absorption phenomenon when target elements in a sample absorb light of specific wavelengths. First, the sample is converted into a measurable form through pre-processing steps such as gas combustion and high-temperature drying. Then, light corresponding to the wavelength of the target element is passed into the sample, the light intensity absorbed by the sample is measured, and compared with a titanium standard solution of known concentration to calculate the titanium content in the sample.

Inductively coupled plasma mass spectrometry (ICP-MS)

ICP-MS is a highly sensitive analytical technology suitable for determining titanium content in liquid and solid samples. This method converts the sample into charged particles, which are then mass-analyzed using a mass spectrometer. ICP-MS has a wide detection range and high resolution, and can simultaneously determine the content of multiple elements. For the detection of titanium, ICP-MS can provide very low detection limits and high accuracy.

X-ray fluorescence spectrometry (XRF)

XRF is a non-destructive analytical method suitable for the determination of titanium content in solid and liquid samples. This method determines the element content in the sample by irradiating X-rays generated on the surface of the sample and measuring the characteristic peak intensity of the fluorescence spectrum in the sample. XRF has the advantages of fast speed, easy operation, and the ability to measure multiple elements simultaneously. However, XRF may be interfered with and cause larger errors in the analysis of low titanium content.

Atomic fluorescence spectrometry (AFS)

AFS is a highly sensitive analytical method suitable for analyzing titanium content in liquid and gas samples. This method uses an excitation source to excite atoms in a sample and measures the intensity of fluorescence light of a specific wavelength emitted in the sample to determine the element content in it. AFS is highly selective, has extremely low detection limits, and enables rapid analysis.

Inductively coupled plasma optical emission spectrometry (ICP-OES)

Inductively coupled plasma optical emission spectrometry is a highly sensitive and highly selective analysis method that is widely used in multi-element analysis. It works by atomizing the sample and forming a plasma, which determines the specific wavelength and intensity of the element’s emission in a spectroscopic instrument.